What is Maintenance Hole Testing?

Maintenance hole testing is a test to see if a maintenance hole, access chamber or a confined space which is buried in the ground is leaking.

Why do we need maintenance hole testing?

How is a Maintenance Hole Tested?

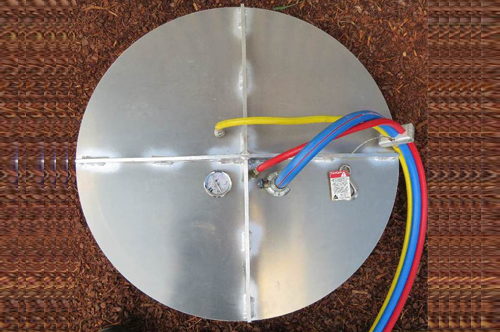

A maintenance hole is tested by either vacuum or hydro-statically both methods we would start by making sure we have a hazard free clean working area that is safe for nearby workers and personnel. We would then do a visual inspection looking for defects, then all penetration will be plugged and propped so the plug cannot move.

A specially designed test cover is placed over the top penetration and vacuum is applied. This is applied until we reach (a negative pressure) of 37 Kpa where we would then close a valve isolating the pump form the test area, then allow pressure to stabilize for at least 3 minutes to identify any initial leakage.

When the pressure has stabilized by allowing the gauge pressure to drop to 33.8 at which time, we commence time recording. We record the amount of time for the pressure gauge to drop to 30.4kpa.The time taken to drop between 33.8 Kpa and 30.4 Kpa is then compared to a table usually found in local authority standards.

The table used by 1CCTV Pty Ltd for the Sydney area is shown below.

The current standards used by 1CCTV Pty Ltd for the Sydney area are: WSA 02-2002-2.2 Sewerage Code of Australia (Sydney Water Edition 1 Version 4)