What is Water Main Hydrostatic Testing?

Why Do We Need Water Main Testing?

How Do We Test A Water Main?

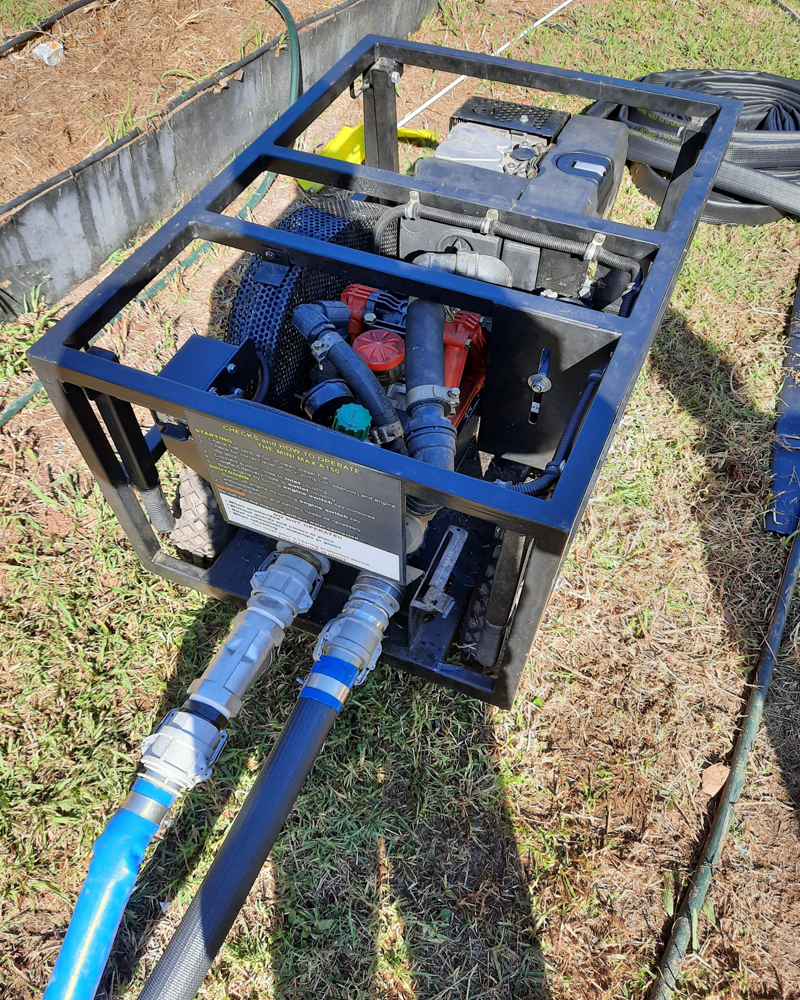

We test a water-main by doing a visual check of the hydrant ends and any visual parts of the main. We would confirm with the contractor that the pipe is ready for testing and all thrust blocks are in position and cured. We can then start filling the water main with clean fresh water from the lowest point in elevation, Filling from the lowest point forces air out the top with little pockets of air getting trapped at connectors, bends and tees. This air can be removed by opening cock valves and hydrants to remove the air as the water level rises to the top of the pipework.

Once the water starts flowing out the top most point and confirming all air has been removed we would close the top hydrant valve then allowing the pipe work to start gaining pressure to normal area mains pressure 450-600 kPa. Once the water main has reached mains pressure, we would separate the filling main from our newly constructed main. Now we can slowly pump high pressure water into our main bringing it up to the required system test pressure. The pressure is then held for set time intervals, if the pressure is to drop at the time interval the amount of water that is required to be added to the main is recorded and added to the report for the corresponding time interval once all time interval have been completed the additional water added is calculated in a specific formula to confirm or deny that the water main passes the test. We also test the clarity of the water-main with a turbidity meter using the 2100Q Portable Turbidity Meter.

The code tested to in Sydney is the WSA 03-2011-3.1 Water Supply Code of Australia (SYDNEY WATER EDITION 2014)