What is pipeline vacuum testing?

Pipeline vacuum testing is a testing procedure to check that the pipeline is not leaking, due to damaged pipe seals and joints or poor installation during construction.

Why do we need pipeline vacuum testing?

Sewer Pipeline vacuum testing is required to verify that a pipeline is not leaking, if a pipeline is leaking outward, it will contaminate the surrounding material with sewerage if a pipeline is leaking inward groundwater will increase treatment costs especially if multiple pipelines are leaking thus putting excessive stress on the local sewerage system, If a pipeline is leaking it will attract tree roots from the surrounding area, which will eventually block the sewer leading to, it backing up and contaminating nearby areas. Testing is also required to make sure pipelines are structurally sound and fit for purpose.

How is a pipeline vacuum tested?

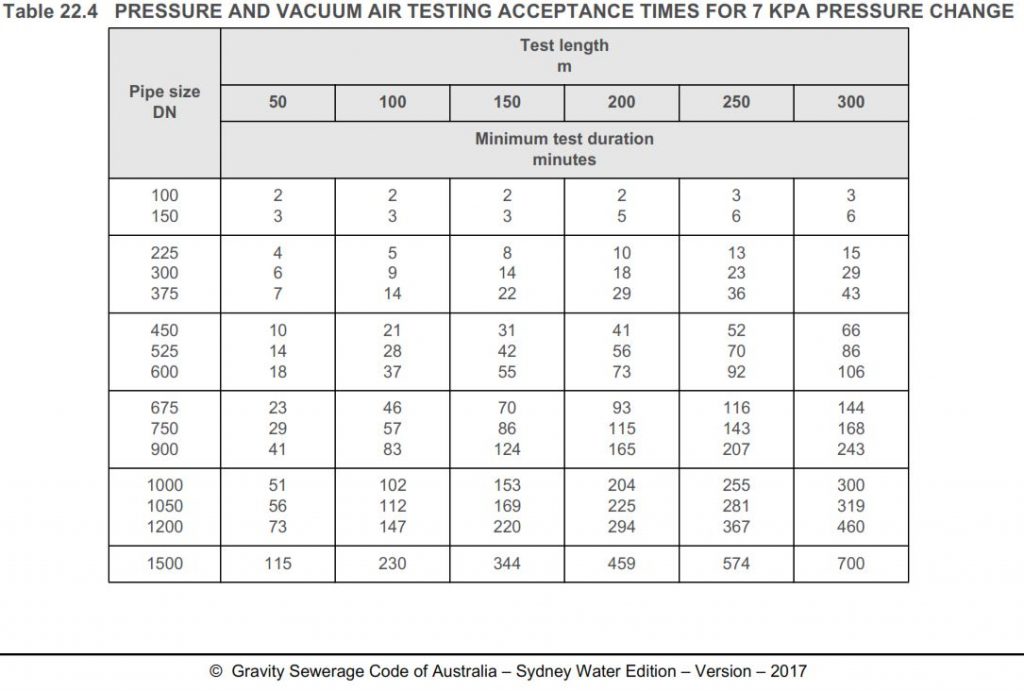

Pipelines are tested by low pressure air or more commonly by vacuuming air out of the pipeline creating a negative pressure, we would start by making sure we have a hazard free clean working area that is safe for nearly workers and personnel. Then all open ends will be plugged and propped so that the plugs cannot move as this will cause damage and can be dangerous. The air is then vacuumed out through a specifically designed test. This is applied until we reach a negative pressure of 27 kPa where we would then close a valve, allow pressure to stabilize for at least 3 minutes to identify any initial leakage. When the pressure has stabilized, we allow the gauge pressure to drop to 23.6 at which time, we commence time recording. We record the amount of time for the pressure gauge to drop to 7 kPa. The time taken to drop between 23.6 kPa down 7 kPa is then compared to a table usually found in local authority standards.

1CCTV Pty Ltd tests to the code at WSA 02-2002-2.2 Sewerage Code of Australia (Sydney Water Edition 1 Version 4)

The table and code used by 1CCTV Pty Ltd in Sydney is shown below.